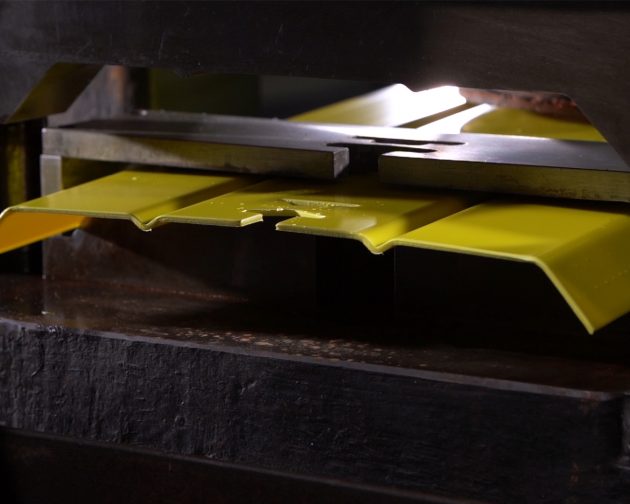

Designed to protect underground telecom and power supply cables, LITAFLEX uPVC Cable Cover Plate (also called the Warning Marker Plate) eliminates disruption to business operations from earth work activities, such as excavation and digging. Manufactured from Polyvinyl Chloride, LITAFLEX uPVC Cable Cover Plate possesses high impact strength and complies with international standards. The wide range of bright, luminous colours with embossed raised lettering enables easy identification, thereby effectively signaling caution when digging trenches. LITAFLEX enjoys the cutting edge in the customization of Cover Plates in the South East Asian region; we have proven expertise in customizing both the colour and the embossed letterings. Furthermore, the ingenious design of the Interlocking Device.

Standard Embossing

DANGER LT CABLE

DANGER HT CABLE

|

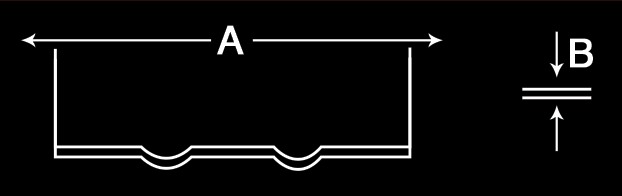

Flat Plate |

||||||

|

||||||

|

Product No. |

Dimension (mm) |

Pallet |

||||

|---|---|---|---|---|---|---|

|

A |

B |

PCS |

M3 |

|||

|

PF 120 |

120 |

1.6 |

2000 |

0.75 |

||

|

PF 150 |

150 |

1.8 |

2000 |

1.00 |

||

|

PF 200 |

200 |

2.0 |

1600 |

1.20 |

||

|

PF 250 |

250 |

2.0 |

1200 |

1.10 |

||

|

Standard Length : 1M |

||||||

|

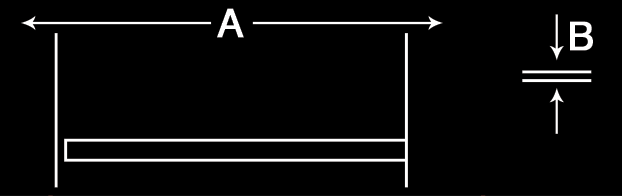

Angle Plate |

||||||

|

||||||

|

Product No. |

Dimension (mm) |

Pallet |

||||

|---|---|---|---|---|---|---|

|

A |

B |

PCS |

M3 |

|||

|

PA 120 |

120 |

1.8 |

2000 |

0.75 |

||

|

PA 150 |

150 |

1.8 |

2000 |

1.00 |

||

|

PA 172 |

172 |

2.0 |

1600 |

1.20 |

||

|

PA 272 |

272 |

2.0 |

1200 |

1.10 |

||

|

Standard Length : 1M |

||||||

|

Flat Smooth Plate |

||||||

|

||||||

|

Product No. |

Dimension (mm) |

Pallet |

||||

|---|---|---|---|---|---|---|

|

A |

B |

RL |

M3 |

|||

|

PS |

200 |

2.0 |

25 |

1.64 |

||

|

Standard Length : 50M per roll |

||||||

CUSTOM-MADE COVER PLATE

COLOURS AND EMBOSSED TEXT

Specifications

|

Characteristics |

272mm uPVC Cable Cover Plate |

|

1. Dimensional Measurement (mm), average a) Length b) Width c) Thickness |

1000 272 2.0 |

|

ASTM D1525 : 2017 2. Vicat Softening Temperature (°C), average |

90 |

|

ONORM E6530 (Clause 7.3) : 1985 3. Impact Strength (Drop Hammer Test) a) Maximim depth of penetration of the 10 kg drop hammer into the 3 specimens tested (mm) b) Observation |

90 No crack was observed |

|

ONORM E6530 (Clause 7.4) : 1985 / ASTM D3045 : 2018 4. Tensile Load of the Longittudinal Connection a) Tensile Load prior to Aging (N), average b) Tensile Load after Aging (N), average c) Change in Tensile Load (%) |

847 869 2.7 |